Specifications

Model | Material | Product width (mm) | Product thickness(mm) | Design linear speed(mm) | Capacity (kg/h) |

JWS 120/150/120-2400 | EVA/POE | 2000~2400 | 0.38~1.0 | 15 | 700~750 |

JWS 180-2400 | EVA/POE | 2000~2400 | 0.38~1.0 | 12 | 600~700 |

JWS 150 | PVB/SGP | 2000~2600 | 0.38~1.52 | 10 | 400~500 |

JWE95-JWE65 | PVB/SGP | 2400~3000 | 0.38~1.52 | 10 | 600~700 |

JWE135-JWE95 | PVB/SGP | 3000~3600 | 0.38~1.52 | 20 | 1000~1200 |

Process steps

Performance characteristics of Jwell EVA film production line:

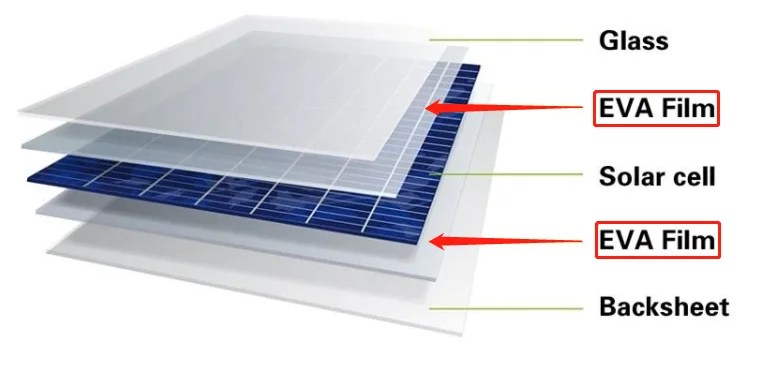

(1) The salivation extruder adopts EVA single screw extrusion, and the screw constant temperature circulating water cooling system solves the technical difficulties of EVA plasticization and non crosslinking.

(2) The roller body adopts double-sided embossing and solves the technical difficulty of adhesive film sticking to the roller.

(3) The cooling part adopts cooling rollers and stress relief cooling beds to ensure smooth operation and full shaping of the adhesive film, ensuring a shrinkage rate of less than 3%.

(4) The entire line adopts PLC fully automatic control to achieve human-machine interface operation.

(5) The production line is equipped with an online quality monitoring and control system to ensure product qualification rate.

(6) Design a micro tension winding machine, with a production line speed of up to 14m/min for the entire machine

EN

EN  ES

ES AR

AR RU

RU TR

TR FR

FR